Your present position: Home > Our Machinas > Extrusion Food Production Line

High Moisture Meat Analogue Production Line

Application: Vegetarian food shops, vegan food restaurants,grocery stores, and food manufacturers.

Capacity: 100kg/h-500kg/h

Certification: CE, ISO9001, SGS

Delivery Time: Around 30 days

Description

High-moisture meat analogue is a vegetable protein product developed in recent years. The main raw material is vegetable protein extracted from soybeans, peas, wheat and other plants. According to the biochemical composition and three-dimensional structure of meat, modern food processing technology and equipment are used. , which accurately simulates the composition and structure of meat, making it a type of plant-based protein product with similar characteristics to animal meat, poultry, and fish in terms of texture, structure, chewiness, and even flavor. Compared with the previous vegetable protein products (usually referred to as textured vegetable protein, etc.), it has a higher water content (the water content of high-moisture protein is 50%-80%, and the water content of non-high-moisture protein is usually lower than 50%). The taste is closer to real meat.

Production line flow chart:

①Raw material processing:

Mixer and fully automatic material handling systems are available as options. The mixer can mix raw material automatically but the raw material must be matched according certain proportion by people in advance. Small capacity production line can configure this mixer; The raw material system can processing the raw materials from weighing, dispensing, to mixing, and even has the function of grinding if needed. So it is more convinient. Large capacity production line can use this material system.

② Raw material transmission:

The screw conveyor is used to transfer the processed raw materials from the mixer to the extruder

③ Destruction and reorganization of protein molecules:

The molecular structure of vegetable protein in the raw material is destroyed and reassembled into a structure similar to meat protein under the high temperature, high pressure and shear force of the extruder。

④ Cooling and shaping:

The protein material in the molten state is cooled and formed into a solid of a specific shape

⑤ Cut and shape into final shape

Here can use a simple cutter or shaper according to the shape of protein you demand

Features:

1. frequency speed controlling with high automation and stable performance.

2. The screws are made of alloy steel and special craft, durable usage, high pressure, the screw life is longer. Adopting the building block structure and combining willingly according to the different demands.

3. The forced lubrication system, can guarantee the equipment transmission life longer.

4. Auto-temperature control system makes the temperature control more direct viewing and the parameter more precise.

5. Self-cleaning, when stopping, can be cleaned without disassembling.

6. According to different screw design rates to full different technology requests.

7. This equipment has wide material, multi-shape products, and flexible collocations. We can produce the different products according to the different models and collocations.

Technical Parameters:

| Model | Installed Power | Capacity | Dimension |

| TSE65-S | 74kw | 100-150kg/h | 15×1.5×2.2m |

| TSE75-S | 160kw | 400-500kg/h | 22×1.7×2.2m |

Video of production hmma:

High-moisture meat analogues:

Parts:

Production process:

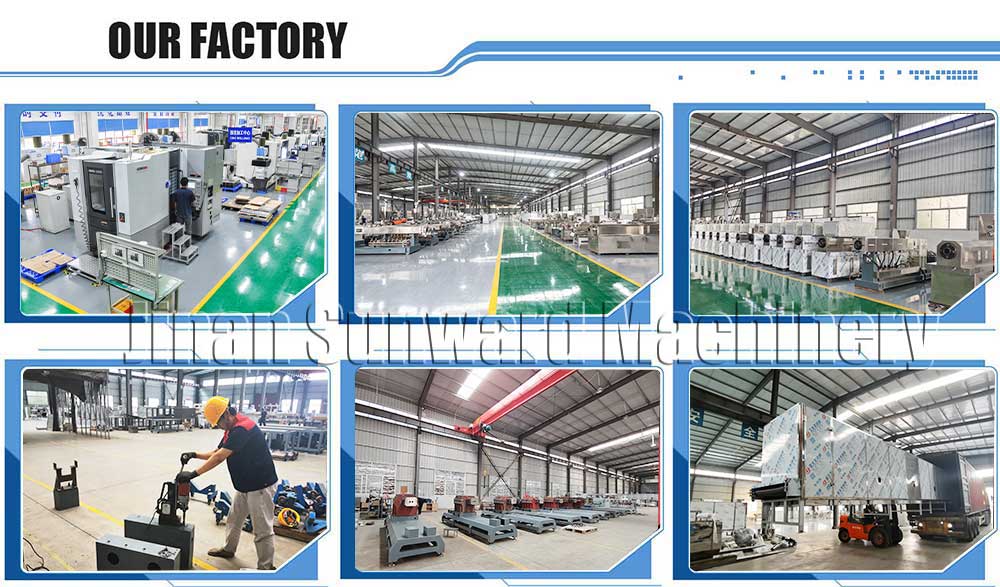

Our factory:

Our team:

Projects:

Packaging and delivery:

Exhibition:

Certification:

Our company has obtained internationally recognized CE certification, SGS certification and ISO9001 certification very early, and has obtained a number of invention patent certificates and other provincial and municipal honor certificates.

FAQ:

Q: How long is your guarantee time?

A: One year after commissioning.

Q: How is the installation?

A: We will dispatch our technicians to your factory to guide you installation and commissioning work and training your operator.

Q: If we show your our layout of the factory, can you help to design the whole process line?

A: Of course, our experienced engineers and technical employee can help you to arrange the layout and installation of the whole production line based on your real situation.

Q: How long is your delivery time?

A: Generally it is 7-10 days if the goods are in stock, or it is 20-25 days if the goods are not in stock, it is according to quantity.

Q: Will you help us if we accrue any problems in future production?

A: Yes, we will always be at your service. You can contact us via mobile, WhatsApp, Wechat, and so on. We will help solve your problems as soon as possible.

Related Products