Your present position: Home > Our Machinas > Extrusion Food Production Line

Pasta Production Line

Application: Grocery stores, restaurants, and food manufacturers can choose the different capacities of the production line according to their demands.

Capacity: 100kg/h-300kg/h

Certification: CE, ISO9001, SGS

Delivery Time: Around 30 days

Description

Pasta is a very popular cuisine which is originated in Italy, but it has already become popular all over the world. Usually, it is made from Duran wheat and is rich in carbohydrates and contains some protein, and low in fat. What's more, there will be many vegetables and other foodstuff been cooked with pasta, besides a variety of sauces and condiments are also good complements when you enjoy it. There are many kinds of pasta, such as macaroni, spaghetti, penne, lasagne, ravioli, and so on. Pasta is divided into two broad categories: dried (pasta secca) and fresh (pasta fresca). Most dried pasta is produced commercially via an extrusion process, although it can be produced at home. Fresh pasta is traditionally produced by hand, sometimes with the aid of simple machines. Fresh pasta available in grocery stores is produced commercially by large-scale machines. Our pasta production line is just the machinery that helps people to make pastas.

The pasta macaroni production line contains a mixer, a screw conveyor, an extruder, a cutting machine, a hoister, a dryer and a cooling machine. The configuration can be changed according to the customer's demand. The pictures of the production line just show only one of the models and part of the machines, so welcome to contact us for more details and quotation at any time, all contact information is valid.

Features:

1. frequency speed controlling with high automation and stable performance.

2. The screws are made of alloy steel and special craft, durable usage, high pressure, the screw life is longer. Adopting the building block structure and combining willingly according to the different demands.

4. The forced lubrication system, can guarantee the equipment transmission life longer.

5. Auto-temperature control system makes the temperature control more direct viewing and the parameter more precise.

6. According to different screw design rates to full different technology requests.

7. This equipment has a wide material, multi-shape products, and flexible collocations. We can produce the different products according to the different models and collocations.

Technical Parameters:

Model

Capacity

Installed Power

Main Motor Power

Dimension

EXT100

80-120kg/h

70kw

30kw

20000×1600×2200mm

EXT100-N

120-200kg/h

130kw

37kw

26000×1600×2300mm

TSE75

200-300kg/h

200kw

55kw

30000×2000×2300mm

Pasta Samples Made By Our Equipment:

Parts:

Production process:

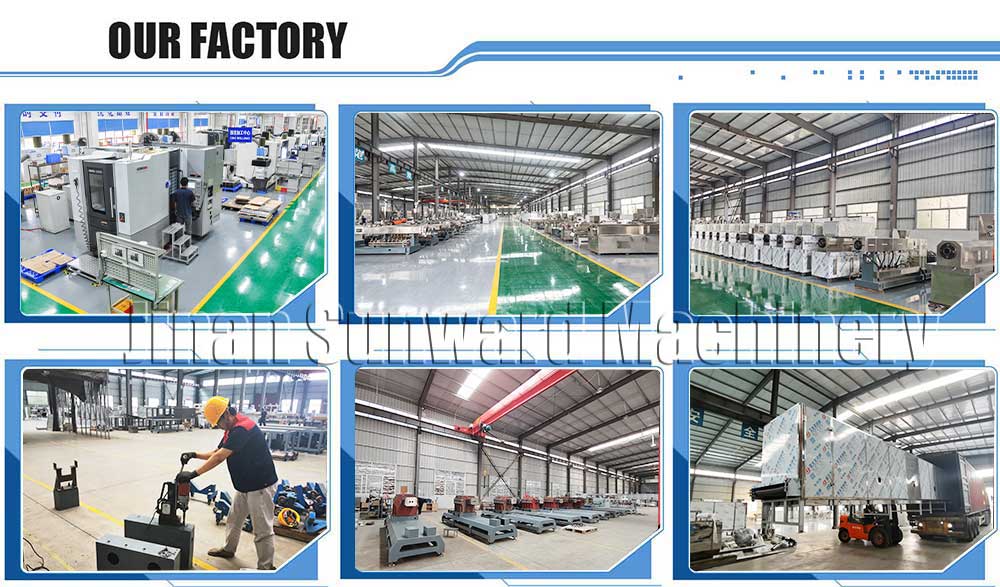

Our factory:

Our team:

Projects:

Packaging and delivery:

Exhibition:

Certification:

Our company has obtained internationally recognized CE certification, SGS certification and ISO9001 certification very early, and has obtained a number of invention patent certificates and other provincial and municipal honor certificates.

FAQ:

Q: How long is your guarantee time?

A: One year after commissioning.

Q: How is the installation?

A: We will dispatch our technicians to your factory to guide you installation and commissioning work and training your operator.

Q: If we show your our layout of the factory, can you help to design the whole process line?

A: Of course, our experienced engineers and technical employee can help you to arrange the layout and installation of the whole production line based on your real situation.

Q: How long is your delivery time?

A: Generally it is 7-10 days if the goods are in stock, or it is 20-25 days if the goods are not in stock, it is according to quantity.

Q: Will you help us if we accrue any problems in future production?

A: Yes, we will always be at your service. You can contact us via mobile, WhatsApp, Wechat, and so on. We will help solve your problems as soon as possible.

Related Products