Your present position: Home > Our Machinas > Food Extruder

Steam Twin-screw Extruder

Application: Food factory, pet and fish food manufacturers, etc.

Capacity: 800kg/h-1200kg/h

Certification: CE, ISO9001, SGS

Delivery Time: Around 15 days

Description

The steam twin-screw extruder is widely used in pet food, fish food and human food industries. It can make pet food (such as cat food and dog food) and fish feed, puffed snacks, bread crumbs, textured soy protein, biodegrade packing peanuts, nutrition powder, etc.

Features:

1. The main extruder adopts frequency speed controlling with high automation and stable per-formation.

2. The screws are made of the alloy steel and special craft, durable usage, high pressure, the screw life is longer. Adopting the building block structure and combining willingly according to the different demand.

3. The forced lubrication system, can guarantee the equipment transmission life longer.

4. International advance steam fittings and imported pressure reduction valve

5. Auto-temperature control system makes the temperature control more direct viewing and the parameter more precise.

6.Self-cleaning, when stopping, it can be cleaned without disassembling.

7. This equipment has the wide material, multi-shape products and flexible collocations. We can produce the different products

according to the different models and collocations.

Technical Parameters:

| Model | Capacity | Installed Power | Main Motor Power | Dimension |

| TSE90 | 800-1200kg/h | 82kw | 75kw | 4700×1200×2500mm |

Samples:

Parts:

Production process:

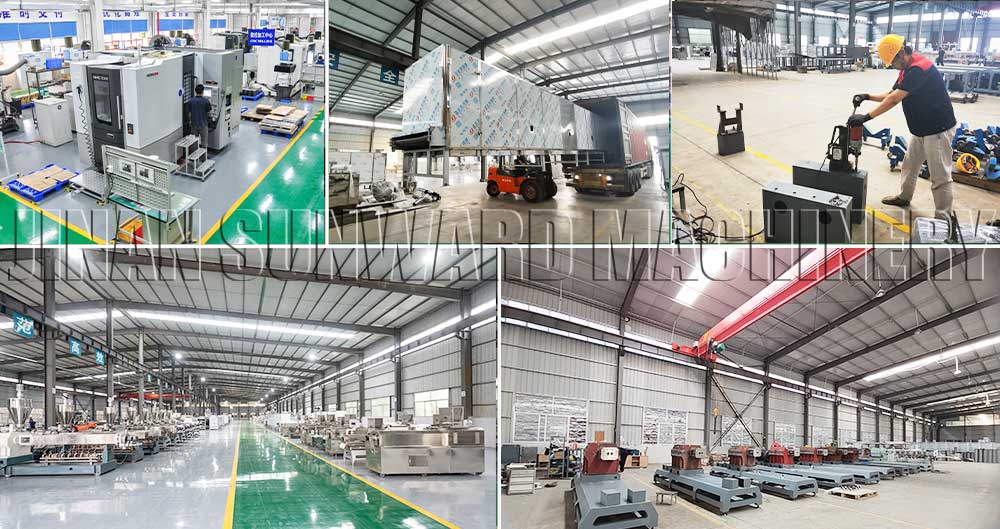

Our factory:

Projects:

Packaging and delivery:

Exhibition:

Certification:

Our company has obtained internationally recognized CE certification, SGS certification and ISO9001 certification very early, and has obtained a number of invention patent certificates and other provincial and municipal honor certificates.

FAQ:

Q: How long is your guarantee time?

A: One year after commissioning.

Q: How is the installation?

A: We will dispatch our technicians to your factory to guide you installation and commissioning work and training your operator.

Q: If we show your our layout of the factory, can you help to design the whole process line?

A: Of course, our experienced engineers and technical employee can help you to arrange the layout and installation of the whole production line based on your real situation.

Q: How long is your delivery time?

A: Generally it is 7-10 days if the goods are in stock, or it is 20-25 days if the goods are not in stock, it is according to quantity.

Q: Will you help us if we accrue any problems in future production?

A: Yes, we will always be at your service. You can contact us via mobile, WhatsApp, Wechat, and so on. We will help solve your problems as soon as possible.

Related Products